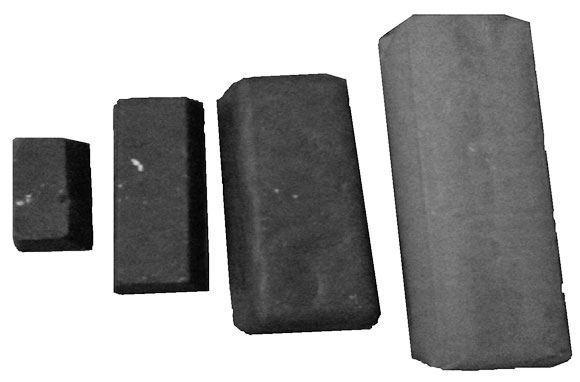

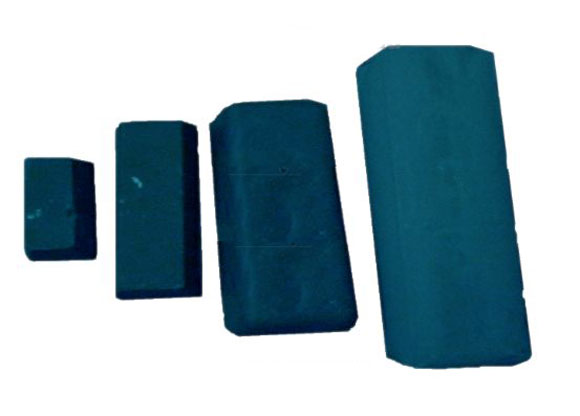

Ausupacut

|

|

|

| Colour |

Grey |

| Part Number |

Size |

Weight |

| BarKAusupacut |

Kit-Kat |

50g |

| BarSAusupacut |

Small |

250g |

| BarAusupacut |

Big |

750g |

| |

Large |

1kg |

|

Used to cut back light scratch marks on most metals. This compound is best used with a sisal buff. It is used for removing 240# to 320# sanding/ linishing marks.

Ausupacut MG

|

|

|

| Colour |

Grey |

| Part Number |

Size |

Weight |

| BarKAusupacutMG |

Kit-Kat |

50g |

| BarSAusupacutMG |

Small |

250g |

| BarAusupacutMG |

Big |

750g |

| |

Large |

1kg |

|

This bar is the greasiest of our cutting compound range. This aids in less friction happening during the procedure. Suitable for all metals to cut back light scratch marks, 240# to 320# sanding/linishing marks.

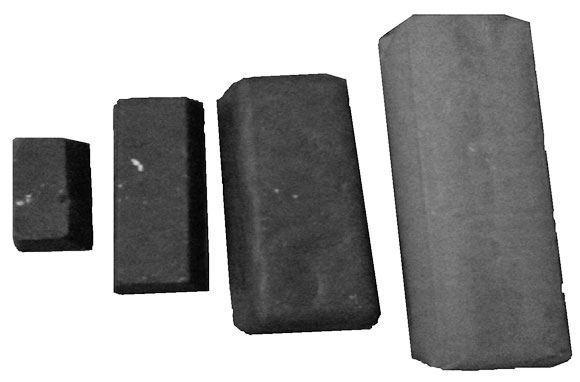

Ausbrax

|

|

|

| Colour |

Dark Grey |

| Part Number |

Size |

Weight |

| BarKAusbrax |

Kit-Kat |

50g |

| BarSAusbrax |

Small |

250g |

| BarAusbrax |

Big |

750g |

| |

Large |

1kg |

|

This is the coarsest compound in our range. It is suitable for most metals and is best used with a sisal buff. Due to the coarseness of this bar it is not recommended to be used for colouring. It is used for removing 180# to 240# sanding / linishing marks.

ATO32

|

|

|

| Colour |

Brown |

| Part Number |

Size |

Weight |

| BarKAT032 |

Kit-Kat |

50g |

| BarSAT032 |

Small |

250g |

| BarAT032 |

Big |

750g |

| |

Large |

1kg |

|

This is our general purpose Tripoli. Tripoli is used on softer metals such as aluminium, brass, copper and zinc. It is a combined cutting and finishing compound. If a brighter surface is required you can follow up with a finishing compound.

ATO32 D

|

|

|

| Colour |

Brown |

| Part Number |

Size |

Weight |

| BarKAT032D |

Kit-Kat |

50g |

| BarSAT032D |

Small |

250g |

| BarAT032D |

Big |

750g |

| |

Large |

1kg |

|

This is a slightly drier Tripoli. It can be used with a Stitched Rag or Stitched Calico mop on alloys, die casts and aluminium.

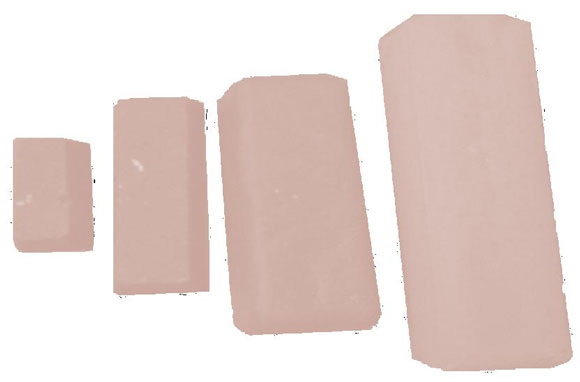

ATO32 DX

|

|

|

| Colour |

Pink |

| Part Number |

Size |

Weight |

| BarKAT032DX |

Kit-Kat |

50g |

| BarSAT032DX |

Small |

250g |

| BarAT032DX |

Big |

750g |

| |

Large |

1kg |

|

This is the driest Tripoli we have in our range. Tripoli compounds retain their ability to cut for a relatively long period of time on our polishing mops due to the particles that they are made of.

Briteshine

|

|

|

| Colour |

Blue |

| Part Number |

Size |

Weight |

| BarKBriteshine |

Kit-Kat |

50g |

| BarSBriteshine |

Small |

250g |

| BarBriteshine |

Big |

750g |

| |

Large |

1kg |

|

The blue bar is a multi purpose finishing compound that is suitable for all metals. It is a dry finishing compound with a fine abrasive. It is best used on all cotton buffs.

SF Hyfin

|

|

|

| Colour |

White |

| Part Number |

Size |

Weight |

| BarKSF |

Kit-Kat |

50g |

| BarSSF |

Small |

250g |

| BarSF |

Big |

750g |

| |

Large |

1kg |

|

This compound is used for cutting and finishing. It is fast cutting with a medium to high finish and is clean. This can be used on a Sisal for some extra cut. It can also be used on Stitched Rag, Calico Buffs and both treated or untreated Airflows and Coolairs.

BBB

|

|

|

| Colour |

Dark Green |

| Part Number |

Size |

Weight |

| BarBBB |

Small |

250g |

|

This green bar is used to bring most metals to a high quality shine like a mirror. Best used with one of our many cotton buffs.

Greaseless Compound

|

|

|

| Colour |

Brown |

| Part Number |

Grade |

Weight |

| BarSatin#80 |

80 |

1kg |

| BarSatin#120 |

120 |

1kg |

| BarSatin#150 |

150 |

1kg |

| BarSatin#180 |

180 |

1kg |

| BarSatin#240 |

240 |

1kg |

| BarSatin#320 |

320 |

1kg |

|

This greaseless bar is for coating mops and felt bobs. It can be used for producing decorative satin finishes, deburring, flash removal or fine ground efforts. It is available in a range of grits ranging from 80# to 320#.

Stearene

|

|

|

| Colour |

Off White |

| Part Number |

Size |

Weight |

| BarStearene |

Standard |

750g |

|

This compound contains no abrasives and is used to lubricate and prevent the clogging of abrasives. It also works well in lubricating blades, belts and satin finishing wheels.

Bobbing Grease

|

|

|

| Colour |

Off White |

| Part Number |

Size |

Weight |

| BarBobbing |

Standard |

750g |

|

This compound is greasier than the Stearene. It can be used to lubricate cutting discs and belts, satin finishing wheels and felts.

Aluminium Oxide Powder

|

|

|

| Colour |

Grey |

| Part Number |

Grit Grade |

Weight |

| AOP#40 |

40# |

1kg |

| AOP#60 |

60# |

1kg |

| AOP#80 |

80# |

1kg |

| AOP#90 |

90# |

1kg |

| AOP#120 |

120# |

1kg |

| AOP#150 |

150# |

1kg |

| AOP#180 |

180# |

1kg |

| AOP#220 |

220# |

1kg |

| AOP#240 |

240# |

1kg |

| AOP#320 |

320# |

1kg |

|

Aluminium Oxide is very fine Aluminium particles that range from 40# to 320#; used for cutting and polishing. Aluminium Oxide can be used in conjunction with Coldax Cement to make grit wheels.

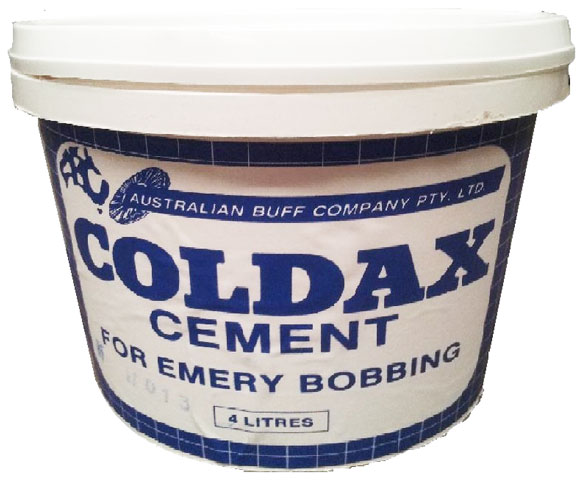

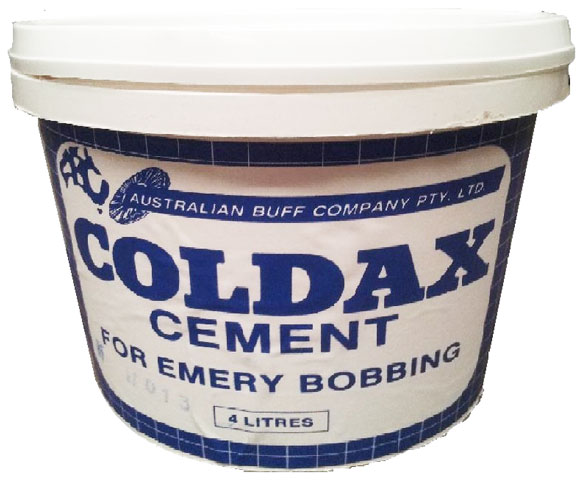

Coldax Cement

|

|

|

| Part Number |

Size |

Weight |

| Coldax |

375ml |

400g |

| Coldax |

1Litres |

1.90kg |

| Coldax |

4Litres |

7.5kg |

|

Coldax is used for bonding abrasive grain onto rag mops to create a soft acting finishing wheel. The application involves rolling the edge of the mop in the Coldax before rolling it in the desired grade of abrasive grain. This product can be air or oven dried.